Why European Manufacturers Rely on Component-Level Repair Services

In today’s fast paced manufacturing world, efficiency, cost effectiveness, and sustainability are top priorities. European manufacturers, in particular, are increasingly turning to component-level repair services provided by experts like FMG Electronics to meet these goals. Instead of replacing entire machines or systems when something goes wrong, these manufacturers focus on repairing individual components. This approach has proven to be highly beneficial, both economically and environmentally.

The Financial Advantage: Reducing Costs

The most immediate and compelling reason for using component-level repair is the dramatic cost reduction it offers.

-

Avoid High Replacement Costs: Manufacturing components—especially those containing specialized circuitry, high grade metals, or proprietary technology—can cost a fortune to replace brand new. A refurbished or repaired component, on the other hand, can often be acquired or fixed for a fraction of the cost, sometimes saving the manufacturer up to 80%. This is particularly true for older or legacy equipment where replacement parts might be scarce or discontinued.

-

Lower Inventory Costs: By repairing existing parts, manufacturers reduce the need to keep large, expensive inventories of new spare parts on hand. This frees up significant capital and reduces storage overheads. Instead of stocking dozens of replacement circuit boards, they might only need a few spares while the rest are being serviced.

-

Preventing Production Downtime: While the direct repair cost is low, the greatest financial impact comes from minimizing production halts. Component level repair services are often much faster than sourcing and shipping a new part from an international supplier. Faster turnaround times mean the assembly line or critical machinery is back online sooner, preventing costly downtime that can run into thousands of euros per hour.

Efficiency and Reliability: Getting Back to Work Fast

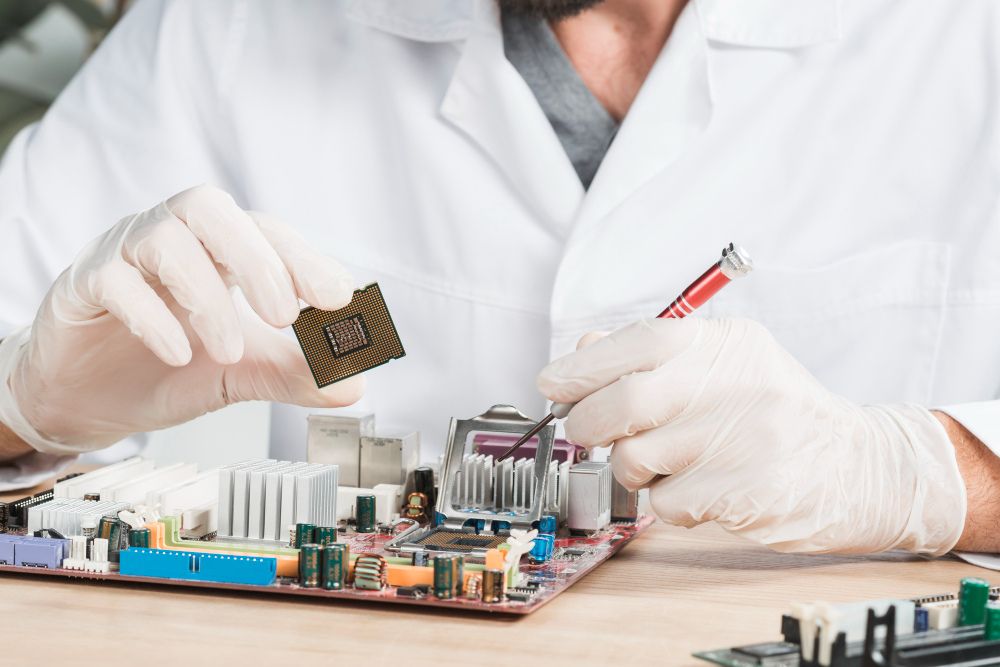

Modern CLR services aren’t just about sticking a bandage on a broken part; they represent a high tech process that enhances the overall reliability of the equipment.

-

Specialized Expertise: Component-level repair technicians are highly specialized. They don’t just swap out modules; they diagnose and fix the tiny, specific fault on a circuit board (like a blown resistor or a failing capacitor). This pinpoint accuracy ensures that the root cause of the failure is addressed, often leading to a repair that is more robust than the original mass produced part.

-

Preventative Repair: Many CLR services offer preventative maintenance alongside the repair. If a specific component is known to fail frequently, technicians will replace all parts in that critical circuit, even those that haven’t failed yet. This proactive approach significantly extends the lifespan of the entire unit and reduces the chance of future breakdowns.

-

Focus on Core Business: By outsourcing these intricate repairs, manufacturers can keep their in house engineering teams focused on innovation, product design, and core manufacturing processes, rather than spending time on detailed component diagnostics.

Saving Money for Everyone

Replacing a whole board or device costs a lot. Component-level fixes can be 50–80% cheaper. For manufacturers:

- Under warranty, they fix instead of replace, cutting costs.

- Beyond warranty, they charge for repairs but keep customers happy and loyal.

Consumers win too. A cracked phone screen or dead battery doesn’t mean buying new. In France, repair funds have fixed thousands of items cheaply. Businesses save billions by avoiding full replacements, as EU studies show.

Helping the Environment

Europe fights climate change with the Green Deal. Electronic waste (e waste) is a big problem—millions of tons yearly. Throwing away devices wastes rare materials and adds pollution.

Component-level repair keeps products in use longer. It reduces mining for new parts and cuts CO2 emissions. Extending a phone’s life by a few years saves resources. EU rules aim for a “circular economy” where things are reused, not trashed. Repair creates local jobs in shops and cafes, unlike manufacturing often done overseas.

Challenges and Why It Still Works

Not everything is easy. Component level repair needs high skills and tools. Some makers used to hide schematics or pair parts to software, making independent fixes hard. New laws ban most of that, though loopholes exist.

For high value or old equipment, like industrial machines, component repair is often the only option when whole boards are unavailable. In crises, like supply chain issues, these services shine because they rely less on global parts.

Conclusion

In summary, European manufacturers rely on component level repair services because they provide significant cost savings, faster turnaround times, environmental benefits, and high quality standards. Expertise, technical support, and the ability to handle specialized machinery make these services even more valuable.

By focusing on repairing components rather than replacing entire systems, manufacturers can reduce downtime, save money, comply with environmental regulations, and maintain the reliability of their products. This approach has become a strategic advantage in Europe’s competitive manufacturing landscape.